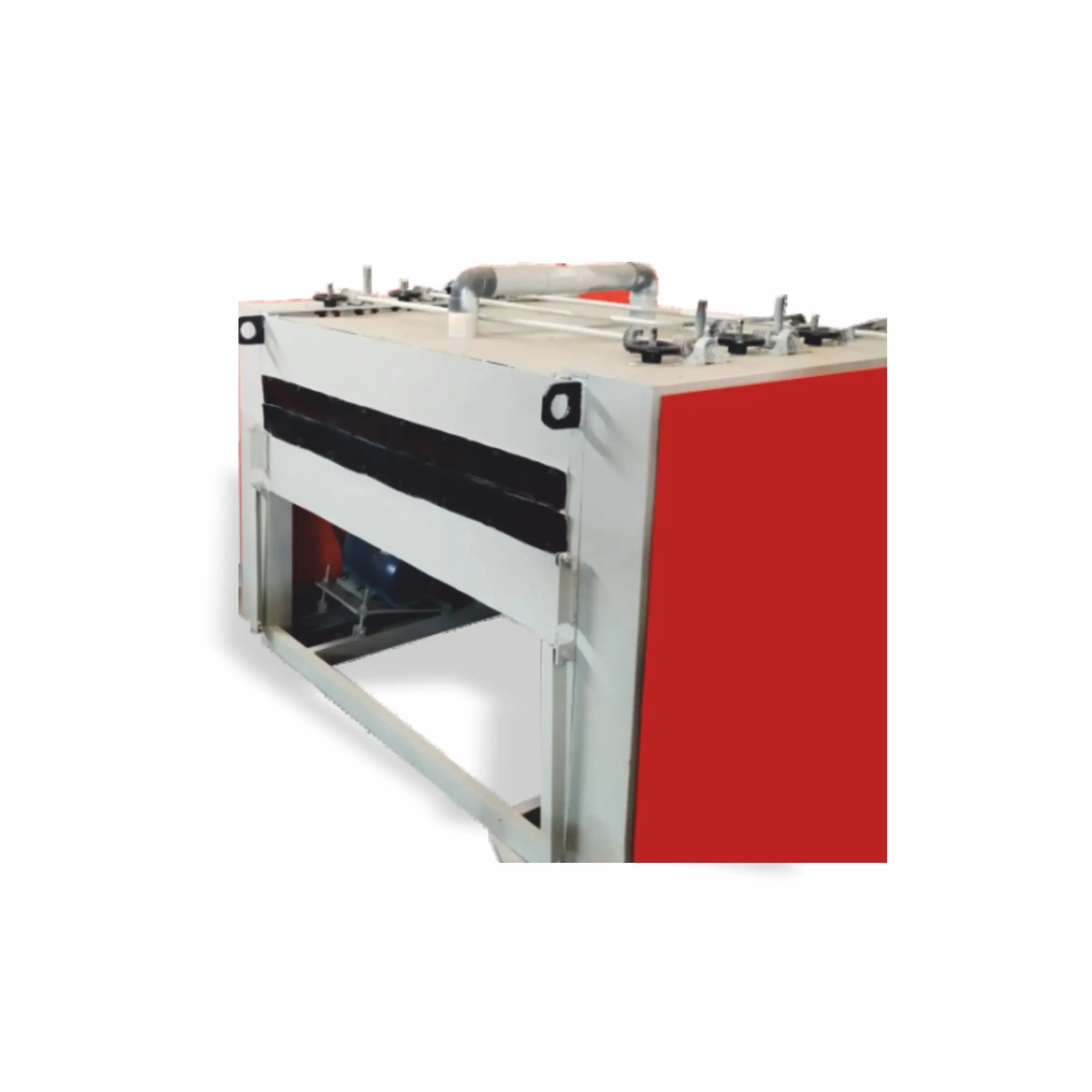

The Steel Wool Machine (Double Side) is a high-performance finishing solution designed to deliver smooth polishing and surface refinement for plywood, boards, and doors. Built with a heavy-duty M.S. fabricated structure, this machine ensures exceptional durability and strength for long-term industrial use. Its robust construction allows stable performance even during continuous operations, making it an ideal choice for plywood industries and furniture manufacturing units.

Engineered with advanced feeding and brushing systems, the machine is equipped with multiple feeding rollers and brush rollers that provide uniform polishing on both sides simultaneously. The precision brushing mechanism enhances surface quality by removing imperfections and delivering a consistent finishing result. This double-side operation improves productivity while maintaining high finishing standards across various wood processing applications.

Designed with original branded bearings and a strong chain and gear mechanism, the Steel Wool Machine ensures smooth and reliable performance with minimal vibration. The heavy-duty plate structure adds extra strength, allowing the machine to handle demanding workloads efficiently. With integrated panel controls and a dust collector system, operators can maintain a clean working environment while achieving precise finishing results.

The Steel Wool Machine (Double Side) is developed to provide efficient and cost-effective finishing solutions for industrial production lines. Its powerful motor configuration, durable structure, and advanced polishing technology make it suitable for continuous finishing operations. This machine enhances productivity, improves surface quality, and delivers consistent polishing performance for plywood, board, and door finishing applications.

Heavy-duty M.S. fabricated structure for durability and machine strength

Equipped with 6 feeding rollers for smooth material movement

Four brush rollers for double-side polishing performance

Original branded bearings for smooth and efficient operation

16 mm heavy-duty plate structure for added strength

3/4 inch chain and gear system for stable performance

Control panel included for easy machine operation

Dust collector included for clean and safe working environment

Motor configuration: 7.5 HP, 7.5 HP, 3 HP, and 2 HP

Uniform finishing polish for plywood, boards, and doors

Smooth operation with minimal vibration during continuous use

Low maintenance design suitable for heavy industrial applications

Copyright © Shakti Engineering Works (SEW). All Rights Reserved.