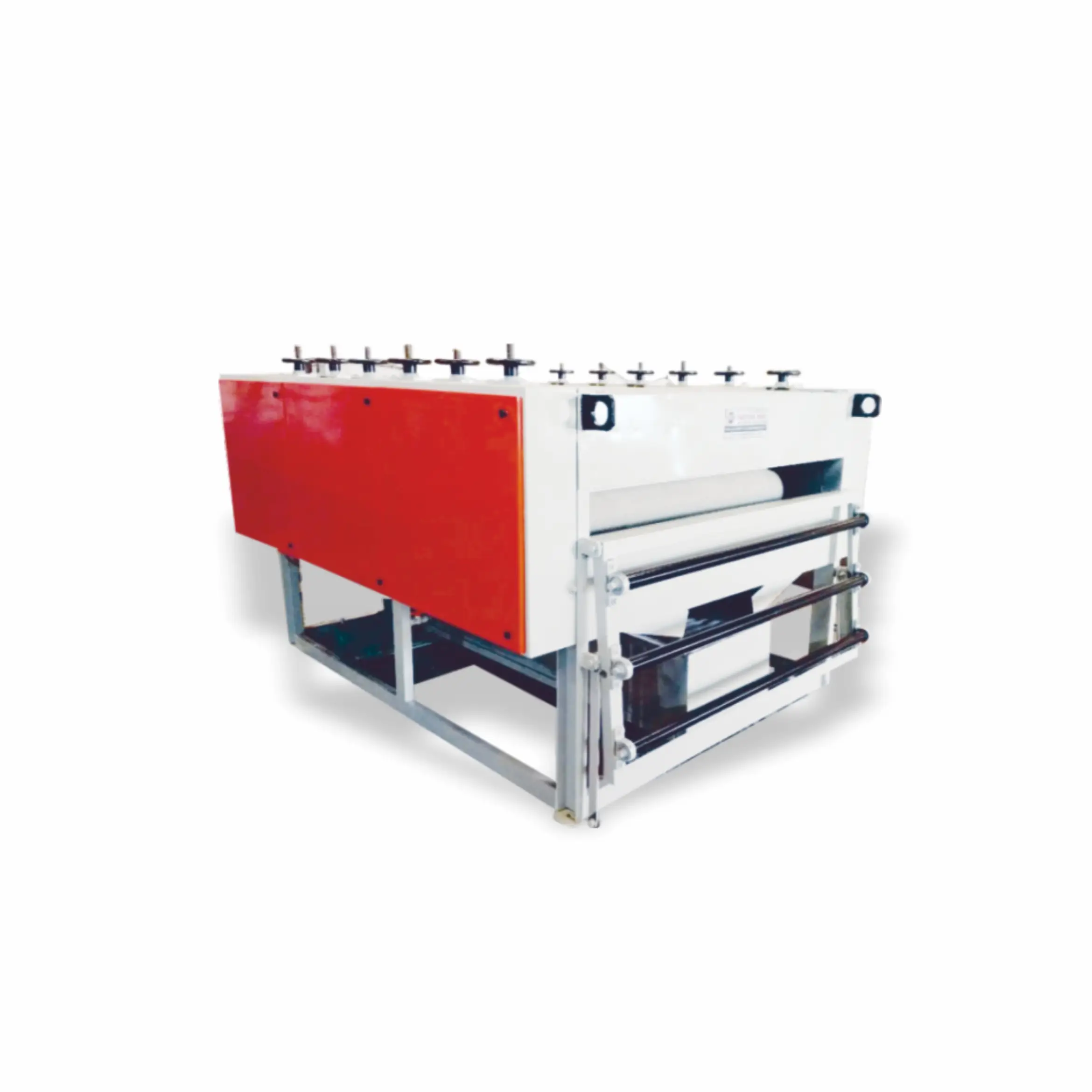

The Plywood Dipping Machine (Manual) is a reliable industrial solution designed for uniform chemical coating of plywood, boards, and doors. Built with a heavy-duty M.S. fabricated structure, this machine ensures durability, strength, and stable performance even during continuous production operations. Its strong structural design makes it suitable for demanding industrial environments where consistent coating and long service life are essential.

Engineered with advanced feeding technology, the machine is equipped with multiple heavy-duty rubber rollers that provide smooth and controlled material movement throughout the dipping process. The stainless steel tank with large capacity allows efficient handling of chemical solutions, ensuring even coating across surfaces. This design improves productivity while maintaining consistent finishing quality for various wood processing applications.

The machine features original branded bearings and a strong chain and gear system that ensures smooth operation with minimal vibration. The manual wheel adjustment system allows operators to easily control size settings according to production requirements. With an included control panel and efficient motor configuration, the Plywood Dipping Machine (Manual) delivers dependable performance while remaining easy to operate.

Designed for efficiency and low maintenance, this machine offers a cost-effective solution for industrial chemical coating applications. Its durable structure, reliable feeding system, and precise manual adjustment mechanism make it ideal for plywood industries seeking consistent coating results. The Plywood Dipping Machine (Manual) enhances workflow efficiency, improves surface finishing, and ensures long-term operational reliability.

Heavy-duty M.S. fabricated structure for strength and durability

Equipped with 12 heavy-duty feeding rubber rollers (approx. 210 mm diameter)

Stainless steel tank with around 300-liter capacity

Original branded bearings for smooth and reliable performance

16 mm heavy-duty plate structure for added strength

3/4 inch chain and gear system for stable operation

Manual wheels provided for easy size adjustment

Control panel included for convenient machine operation

Motor configuration: 5 HP / 1440 rpm & 1 HP / 1440 rpm

Uniform chemical coating for plywood, boards, and doors

Smooth feeding system with minimal vibration

Low maintenance design suitable for industrial use

Copyright © Shakti Engineering Works (SEW). All Rights Reserved.